About This Project

In 2019 Fussy Cat introduced their new chilled range. Their new raw meat range is minimally processed and includes plenty of fresh and great tasting ingredients in convenient, single-serve portions.

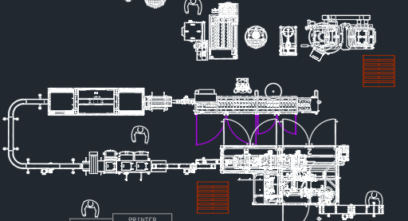

The new production line consisted of a Mixing system, Makum product filling system, Ulma Tray Sealer, HMPS packaging system and conveyors.

Industrial Power and Automation was tasked with the automation scope of this project.

This project consisted of:

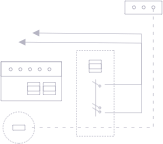

- 1x MCC panel

- 1x HMI control panel

- 2x RIO panels

- 8x Motors

- Integration of 3rd party equipment to the production line

- Mackum Filling System

- Ulma Tray Sealer

- HMPS case packer

Our scope of works included:

- Automation and control of conveyor system

- Integration of 3rd party equipment to the packing system

- PLC/HMI programming

- Conduct a Factory Acceptance Test (FAT)

- On-site commissioning, IO testing, and validation of equipment