Our RCD Testing Gold Coast team can help with all testing & installation services

Industrial Power and Automation provides RCD testing services for commercial and industrial clients across the Gold Coast as well as RCD testing in Brisbane. Our skilled electricians use the latest technology to provide you with efficient and cost-effective solutions.

Our management software can log your assets and keep a detailed record of their service history, as well as send reminders when the next inspection is due. This leaves you to focus on what’s important, running your business.

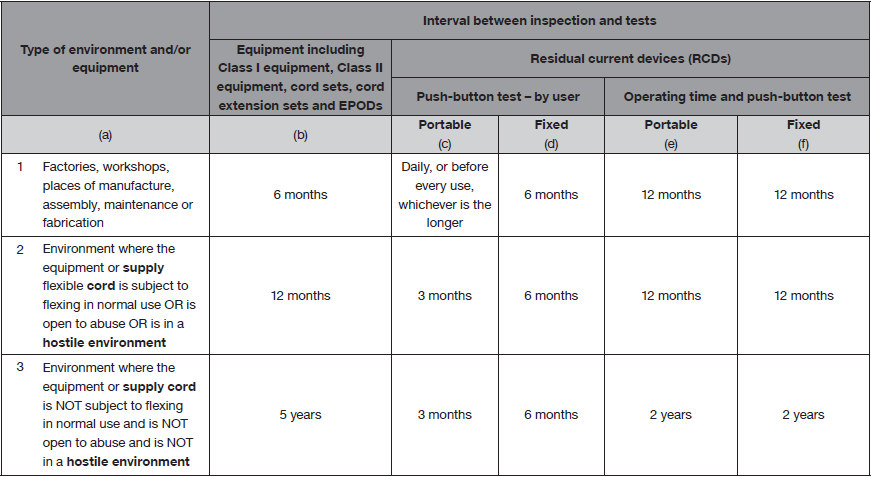

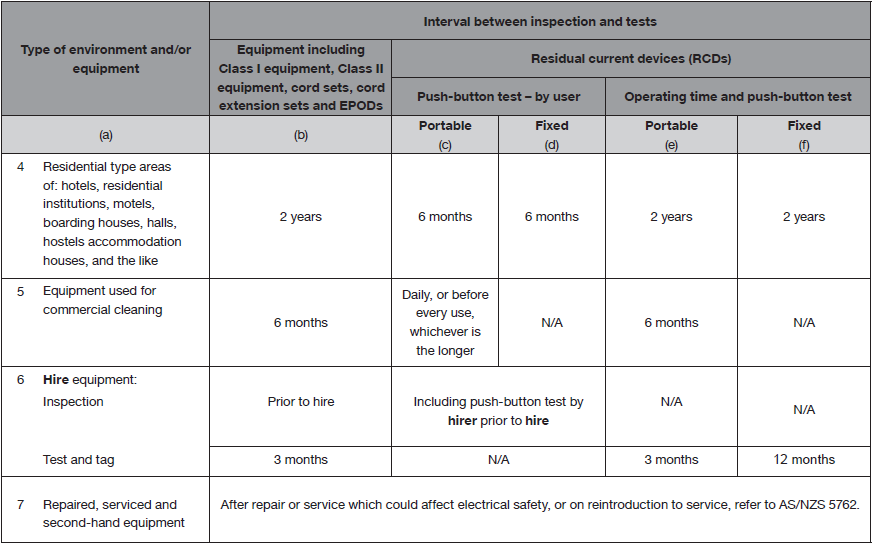

If you are a business owner it is your obligation to ensure the safety of your workplace, and that includes regular testing of your electrical equipment. Queensland workplace health and safety state testing intervals from 3 months to 5 years depending on which industry you operate in.

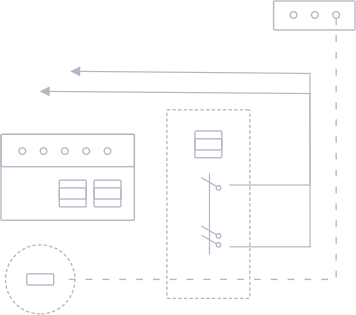

A residual current device (RCD), commonly known as a safety switch, is a device that prevents dangerous electrical shocks from occurring.

Residual current devices need to be regularly tested to ensure they remain in correct working order as they will only provide ongoing protection if operational.

Our RCD testing includes:

- Compliance check

- Visual Inspection

- Push Button Test

- Trip time at 0˚

- Trip time at 180˚

After our testing is completed, any faulty items are reported immediately, and repairs are arranged if required. All test results are fully documented and supplied upon completion.

The frequency of their testing is outlined in AS/NZS 3760 Table 4. This table outlines the in-service safety inspection, testing method and frequency.

We also offer compliance testing services. This ensures your equipment is always in compliance with safety standards.

Our other compliance testing services include:

Emergency Light Testing

Emergency and exit lighting must be inspected, tested, and maintained in accordance with the AS/NZS 2293 Standard. Commercial emergency lighting and exit lighting systems are governed by the law.

All emergency and exit lights must undergo a 90-minute discharge test of the battery every 6 months as stated under the AS2293.2 Standard. Records of all tests and the subsequent actions taken must be kept for compliance purposes.

Test and Tagging

Test and tagging in Brisbane and test and tagging on the Gold Coast the process of inspecting and testing electrical equipment for safety in accordance with the test & tag frequencies outlined in the AS/NZS3760 Standard.

The process for test and tag is completed in two stages. First the equipment is visually inspected for any damage, then it is electrically tested to ensure there are no internal faults.

Thermal Imaging – Infrared Thermography

Thermal imaging in Brisbane and thermal imaging on the Gold Coast find hot spots caused by loose connections and defects in components. It detects problem areas so that failure or damage can be avoided ahead of time.

Industrial Power and Automation uses the latest technology in scanners which can detect electrical faults often missed by traditional methods of testing.

We are certified in Thermographic Scanning and our qualified technicians are recognised by the Australian Institute for Non-destructive Testing (AINDT).

RCD Testing Gold Coast

IPA is the most trusted RCD testing provider on the Gold Coast. We have been in business for years and have tested thousands of RCDs for both industrial and commercial customers. Our trained and certified technicians use state-of-the-art testing equipment to ensure that your RCD is functioning properly. We also offer a wide range of RCD testing services, including monthly testing, annual testing, and one-time testing for new installations. In addition, we offer a money-back guarantee if you are not satisfied with our services. With our experienced team and commitment to customer satisfaction, you can be sure that IPA is the best choice for RCD testing in South East Queensland.

What is RCD Testing?

RCD testing is a type of electrical safety testing that is used to ensure that electrical circuits are safe to use. RCD stands for Residual Current Device, which is a safety device that is used to detect and interrupt the flow of electric current when electricity is detected at dangerous levels. RCDs are typically used in industrial and commercial settings to protect people from electrocution. RCD testing is conducted by qualified electricians who can check that the RCD is functioning correctly and that the right level of protection is in place. In some cases, RCD testing may also be required by building regulations.

RCD Testing Requirements QLD

In Queensland, all new and altered electrical work must be inspected and tested by a licensed electrician to ensure compliance with the Australian Standard. As part of this process, the electrician will carry out an RCD test to ensure that the Residual Current Device (RCD) is functioning correctly. To test the RCD, the electrician will first turn it off and then back on again. They will then measure the time it takes for the RCD to trip and make sure that it trips within 0.4 seconds. If the RCD does not trip within this time frame, it will need to be replaced.

Why Choose Us For Your RCD Installation and Testing

We are an Industrial and Commercial electrical contracting company who specialises in RCD Installation and Testing. With our extensive knowledge and experience, you can count on us to provide your business with a comprehensive RCD solution.

Our technicians are highly experienced in asset maintenance and compliance testing. You can rest assured that with our comprehensive service, your equipment will meet electrical safety standards.